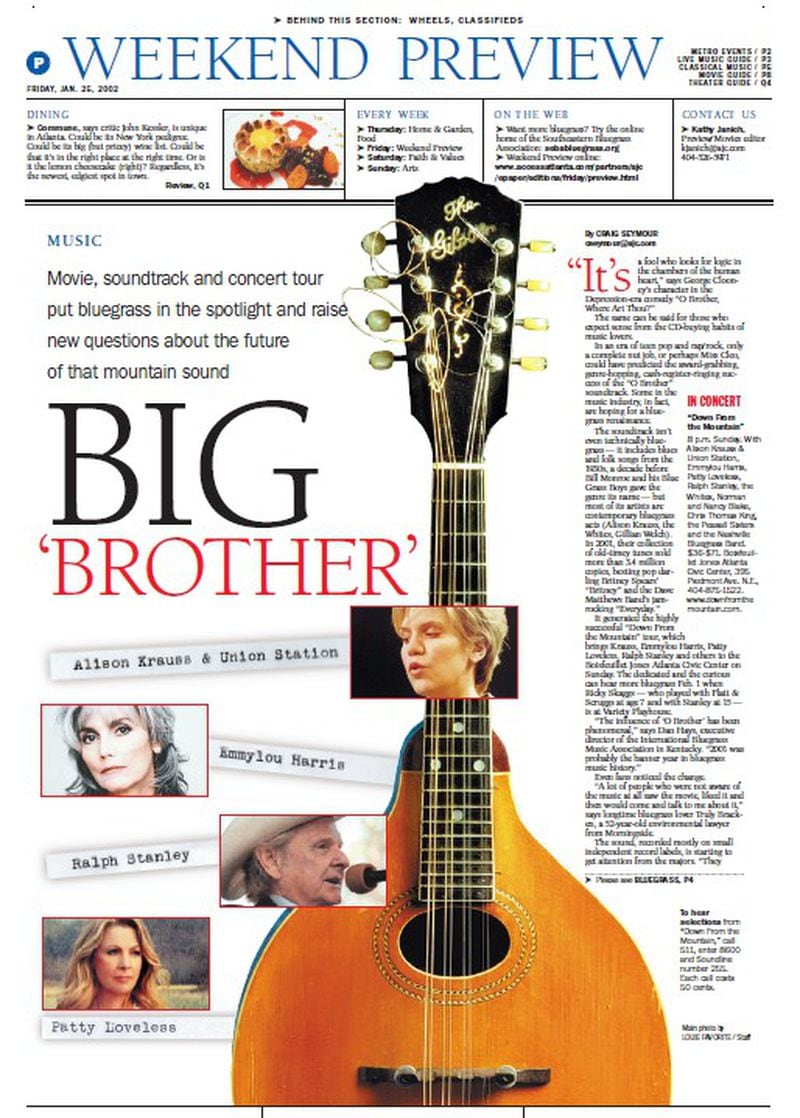

The mandolin is a beautiful, strange, difficult instrument, tuned like a violin but with a flat, fretted fingerboard and eight strings instead of four.

Played with a plectrum, it is capable of producing chopped chords that can kick a bluegrass band into gear like Gene Krupa on a 14-inch snare. It can also float lilting melodies that shine like a Frank Capra happy ending.

My mandolin-playing grandfather Dr. William Howell Kiser came from a family that was all about serious music. His grandmother, Lucy Cook Peel, had much to do with bringing the Metropolitan Opera to Atlanta for regular visits. Short and substantial, she can be seen in a photograph posing with Enrico Caruso. They are both exactly the same shape.

Bill Kiser’s family wanted him to play serious music on the violin, but he preferred ragtime and mandolin songs like “I’m So Glad My Mama Don’t Know Where I’m At.”

I never heard him play the violin, but when we celebrated Christmas at his house on Peachtree Circle, my mother would play carols on the piano, we would sing and my grandfather would add mandolin flourishes, his double-stop tremolo soaring above “O Little Town of Bethlehem.”

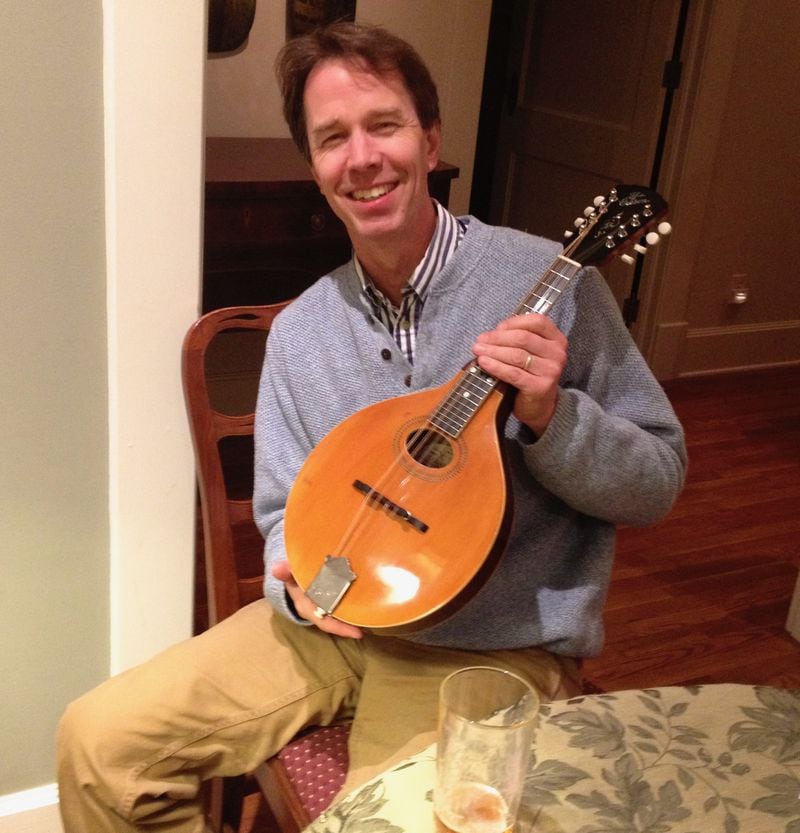

When my grandfather — we called him Toddy — died in 1979, his violins, banjos and mandolins were divided up among his grandchildren. To me came an A-model Gibson that I’m sure he bought new in 1915.

Credit: File

Credit: File

It had a gracefully-arched top the color of Tupelo honey and a subtly curved back the color of chocolate cake. On the headstock was inlay that read “The Gibson” in mother of pearl. Inside the oval sound hole one could spy a label from Kalamazoo, Michigan, that explained “Patented Feb. 1, ‘98.” The label pledged that it was “GUARANTEED against faulty workmanship or material. Should this instrument, with proper care and usage, go wrong, we agree to repair it free of charge at our factory, or replace it with another of same style or value.”

I say “it came to me” because I did not seek it. I had never played a mandolin. My mother and her siblings were responsible for dividing up these treasures, and she made an executive decision: I needed a mandolin.

The case was the original: Hard leather, with soft purple felt on the inside. There was a pitchpipe in the pocket inside. There were four double courses of strings, two each of G, D, A and E, pitched an octave higher than a guitar. The tension on those strings creates the brightness that makes a mandolin so lovely. This instrument was made before the era of the metal truss rod, so the neck was short and thick, in order to handle the stress.

Credit: AJC

Credit: AJC

By the time it came into my hands I was living in Boylan Heights, on a ridge above downtown Raleigh, North Carolina, in a hotbed of artists, hippies, musicians and college students. Across the street was guitarist Richard Hill, whose house was a jam magnet. I took this mandolin that I couldn’t play over there and learned by doing. We played on the porch. We played in the middle of the street. We played on the Boylan Bridge, sometimes climbing up on the girders.

Almost immediately I discovered that Toddy must have dropped this mandolin at some point, because there was a crack all the way around the headstock that widened when the strings were brought into tune. My mandolin had gone wrong.

Credit: Jack Brantley

Credit: Jack Brantley

I knew I would need to get this unasked-for keepsake repaired. I found a certified Gibson repairman named Hoffman who fixed it for $350 (in 1980 dollars), a price that made me choke, but I swallowed my dismay by reassuring myself that it was a family heirloom, and I sort of owed it to the family to keep it playable.

My repairman performed a radical operation on the old wooden box, slicing the headstock off at an acute angle, just at the ebony fretboard, carving a brand-new headstock, including mother-of-pearl inlay, and gluing the new and old together. It sounded great, but I would learn later on that Hoffman probably made a rash and unwise choice.

Credit: Jack Brantley

Credit: Jack Brantley

Nonetheless, in the meantime I was learning “Red-Haired Boy” and “Arkansas Traveler” and struggling to make three-finger chords and play melodies on this new and peculiar device.

The downside of this new instrument was I had to forget what I knew about playing guitar and start over with baby steps. Also, there were eight strings to tend to. My mandolin experience was five minutes of tuning per one minute of playing.

The upside of the mandolin was this: No one else had one. There were a hundred guitar players to every mandolinist. In fact, I didn’t know another mandolin player, so I had nobody to show me the ropes, and I had to make it up as I went along. As a result I learned all kinds of bad habits that were hard to change once I finally found players who knew what they were doing.

In 1915, when my mandolin was glued together, things were different. Mandolin clubs were popular. Schools and communities supported mandolin orchestras. In the photo of Toddy with the Yale mandolin club, there are 22 fellows dressed in their performance tuxedos, two on guitar. I will point out that of all the scions in Toddy’s row, he’s the only one wearing the dress-appropriate patent leather slippers, and they are immaculate.

Credit: Jack Brantley

Credit: Jack Brantley

Hoffman’s radical solution lasted for 10 years. Then the headstock began to creep at the boundary between old and new, and finally gave way. By this time I was living in Atlanta. Bob MacIsaac, of Cedar Hill fame, gave it a quick and dirty re-glue for $175, and it sounded great all over again.

The strings on a mandolin exert about 160 pounds of pressure on the neck and headstock. That’s why they are loud. There is enormous potential bound up in those strings. But my strings were destined to pull my compromised mandolin apart. Bob’s fix lasted another 10 years. Then it began to creep. And it popped apart, yet again.

At this point I had bought a less expensive (at least in 2004 dollars) Chinese-made A-model mandolin for backup. The crippled family heirloom stayed in the case for many years.

Then one day my enormously talented friend Jack Brantley asked about the old Gibson. Jack is not only a superb musician who plays fiddle, harmonica, bass, button accordion and piano accordion, but he is also a craftsman who repairs all manner of instruments. Today he runs Accordionology, and makes a living working on accordions, which are the most grotesquely complex musical instruments ever created, next to the theater organ.

He had a concept in mind, a plan for my mandolin, using a carbon fiber wafer to reinforce that critical joint between the headstock and the neck, a wafer placed perpendicular to the plane of the fretboard. I had been carrying around the original headstock for 30 years or so.

With the help of his colleague, the late Wade Lowe, Jack set aside that interloper headstock with its fake pedigree and took my old peghead (which was considerably lighter than new the one) and went to work.

Credit: Jack Brantley

Credit: Jack Brantley

The result was gorgeous. The sound was singing. The cost was a bargain, considering how many hours Jack put into the job.

You may be disappointed to learn that a couple of years later I was back where I started.

I haven’t given up. I have another plan. I need the neck from a scavenged A-model, a neck with the headstock securely attached. An old neck, attached to my old body: It could work.

In the meantime, this is what I’ve learned: Without my own cash invested in this mandolin, I might have never learned how to play. It might have stayed in the case.

Somehow I felt obliged, once I had skin in the game, to work at it. As a result, I’ve learned enough to have fun playing with friends and sometimes at church. In the interim, the Chinese mandolin still sounds pretty good.

Suffice it to say that, adding the costs of all the repairs together, I could have bought two contemporary mandolins, or even a vintage A-model from the thriving market for old Gibsons.

But if I had, I might never have got the knack of that devilishly beautiful, pumpkin-top, tear-drop-shaped box of strings that Bill Kiser turned into a ragtime joy machine.