Startup targets salmonella with tech

If Arjun Ganesan had been accepted to Stanford University, Connecticut would have missed out on a technology company that has grown to 23 workers so far, with ambitious plans.

Ganesan, who started his first company 14 years ago while an undergraduate in India, applied to prestigious MBA programs around the United States, intending to become a venture capitalist that would help start-up companies expand into Asia.

Stanford didn’t accept him, but Yale did. In 2012, he completed his MBA there.

While he was at Yale School of Management, Ganesan realized he could do more as a founder than an investor, and looked for science ideas developed by Yale professors that could be commercialized.

He convinced former Yale professor Hur Koser to join him in starting Ancera, a company that builds machines that can test more quickly for salmonella than the current methods. Eventually, Ancera intends to use the same machine to screen for listeria, e. coli, or campylobacter bacteria.

The company raised its first investments in November 2012, and has since raised $12.3 million, including $556,000 from Connecticut Innovations, the state-funded venture capital agency.

The Process

Ganesan plans to solicit another multi-million round of funding this year.

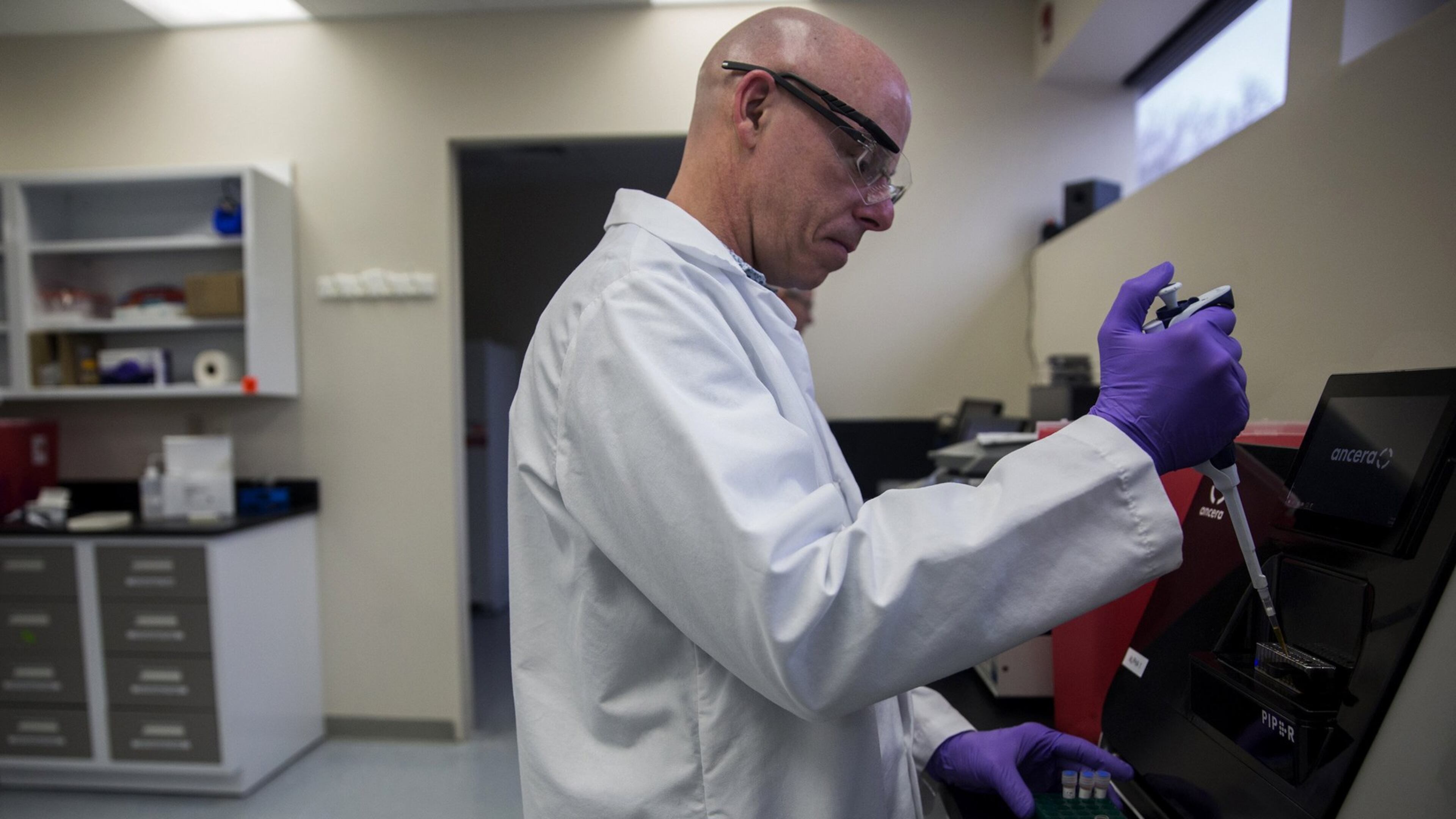

Ancera makes a machine — about the size of a printer — that uses an electromagnet to draw fluid to it. That fluid is infused with nano particles of iron as well as the sample from a chicken carcass. Chicken slaughterhouses are the first application, but the technology could be used with pork, produce or even liquids.

The fluid is moved to a sensor, which can identify if there are live salmonella cells present.

This is an advantage over current technology, which requires growing a culture until it is large enough to use a microscope to detect bacteria on the slide. That process takes 30 hours or more. The Piper is able to detect bacteria more quickly because the MagDrive technology, as Ancera calls the fluid/magnet method, is able to move the relevant cells to the sensor, which means it can detect contamination when there are far fewer cells present.

In less than eight hours, Piper will be able to tell if there’s a spike in the presence of salmonella.

Ancera chose to start its research targeting salmonella in chicken processing plants because it’s the fastest-growing protein source in the world. Ganesan said Americans eat 8.5 billion chickens a year.

Packer Sanitation Services Inc., a cleaning services company that serves 450 food processing plants daily, is one of Piper’s primary investors, and has been testing its machines. In February, Ancera started offering its machines to other customers (though not to competitors of PSSI). It hasn’t had any sales yet.

Ancera contracts with manufacturers to make its machines and disposable cartridges. So far, 10 Pipers have been made, including prototypes, and 35 will be delivered this year, he said.

The company also augments its 23-person staff with about 65 contractors across the last year. They include designers, software coders and more. Ganesan said hiring people for specific projects helps contain costs, which is important when you don’t have revenues yet.

He said about five of the 65 contractors are in Connecticut. Nearly all of the staff is in Branford, and the company just moved to a 28,000-square-foot space to make room for additional staff. Ganesan said they should grow to 35 people by the end of the year. His chief of operations and head of engineering are local, but the vice president of biology and chief financial officer are in Boston, and the chief commercial officer is based in Jacksonville, Fla.

Ganesan said it’s hard to convince senior-level people to uproot their lives and move to Connecticut when the cash on hand will last about a year and a half to two years. And, he said, Connecticut is not the booming hub of pharmaceutical research it used to be, as Pfizer and Bristol Myers Squibb downsized, so those job candidates don’t have confidence they’ll find another job if Ancera doesn’t take off.

Naturally, Ganesan is optimistic Ancera will succeed. He’s projecting the company will break even as soon as 2018, and he’s already anticipating the challenges of hiring to reach 100 employees.

He has no regrets about settling in Connecticut rather than the Silicon Valley. At Yale, he met his wife, a Public Health graduate student who is now in medical school at Quinnipiac University.