Kennesaw State staff members create 3D-printed face shields for hospitals

Kennesaw State staff members are using tools the university has on hand to come to the aid of healthcare clinicians risking their lives to treat patients during the coronavirus pandemic.

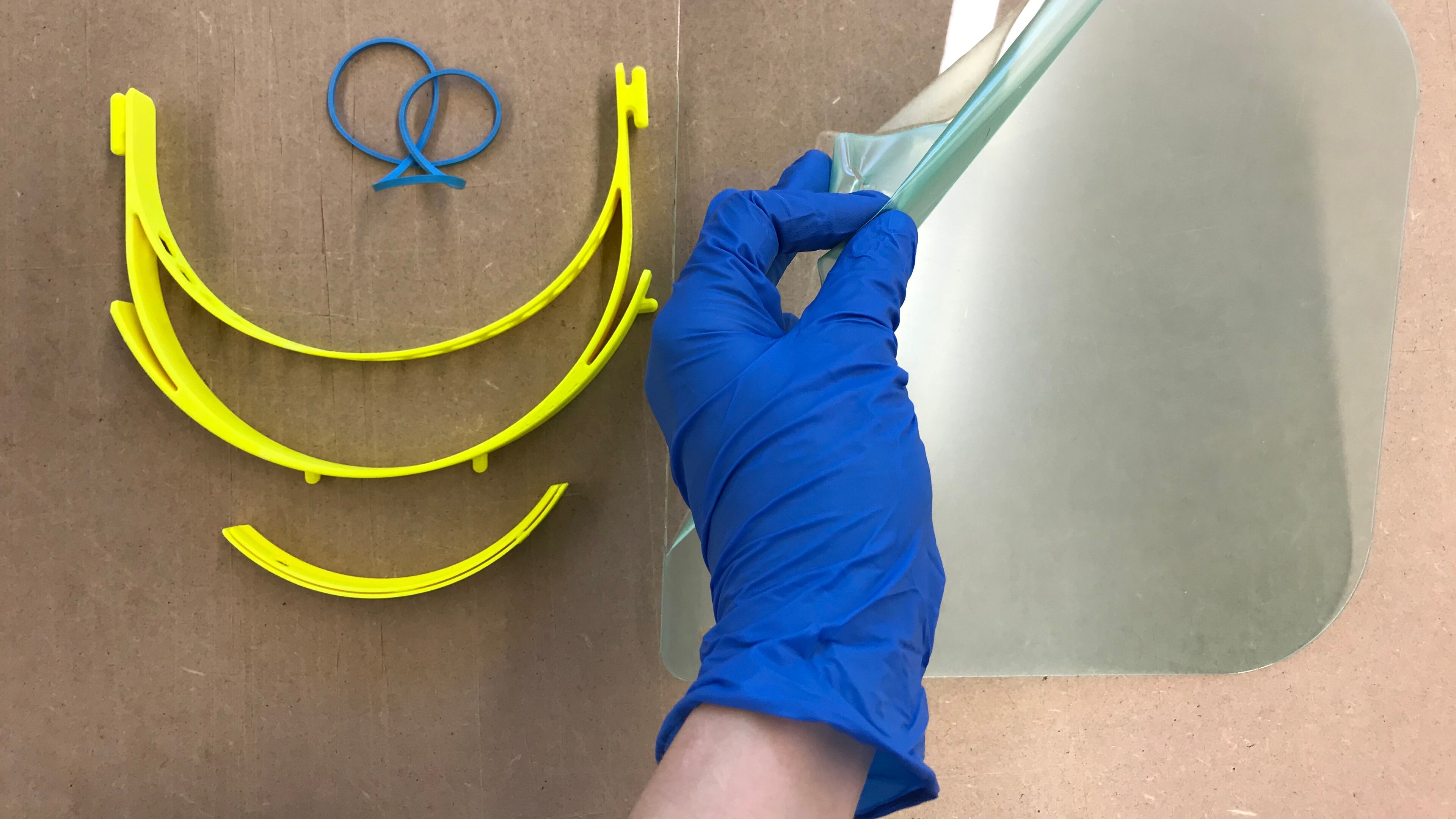

The team is using a 3D printer and laser cutter in the university’s College of Architecture and Construction Management’s Digital Fabrication Lab to create face shields, which protect healthcare workers’ eyes and face from the virus spread by coughs and sneezes of infected patients.

So far, 145 shields have been made by the team. The shields have been shipped to WellStar Cobb Hospital, Cartersville Medical Center and MetroAtlanta Ambulance Service, Kennesaw State University said Tuesday in a news release.

With a donation of materials from Atlanta-based architectural firm YSM Design, the KSU team expects to make an additional 4,200 shields for area hospitals in need.

READ | Georgia Tech researchers make 10K face shields for Atlanta hospitals

It takes about three hours to 3D print one headband for the face shields, but digital fabrication lab tech Rachel Johnson said the team can stack the design to print several at a time. The laser cutter has the ability to cut the mask shield in seconds.

Other team members include fellow digital fabrication lab tech Sabrina Seaman; Rachel Kidd-Chancey, wood shop supervisor; and Dave Peeples, manager of building operations for the Department of Architecture.

“We take pride in being a community-oriented institution, and I am delighted that our staff have joined together to support local medical workers at such a critical time,” said Andrew Payne, dean of the College of Architecture and Construction Management. “They have volunteered countless hours to see this come into fruition and have generated excellent results all while maintaining their primary role of serving our students throughout the current remote learning model.”